When installing a new system or just reinstalling your pipe after cleaning or repacking, these tips will be valuable. The first thing to check is the condition of the gasket in the exhaust port. These are made of a soft material, normally copper and can be reused, but if the header has ever been run loose or over tightened it should be replaced .

Next, anti-seize should be applied to the header mounting studs to insure proper torque reading and makes removing the header later easier. Most of the time installing the header first is the best way to insure that the pipe is aligned correctly (with an after market pipe this might be the only way to install the pipe because of the tight fit of the slip joint).

Installation Procedure

1. After checking or replacing the gasket and applying anti-seize to the studs,

slip the header into place and start the nuts by hand. Do not tighten the nuts just yet. You want the header to be able to rotate.

2. Slip the muffler / mid pipe onto the header. On some bikes, this is a lot

easier if you rotate the assy. 90 degrees to allow the mid mount to pass

the Sub-frame before you rotate it up to its proper position.

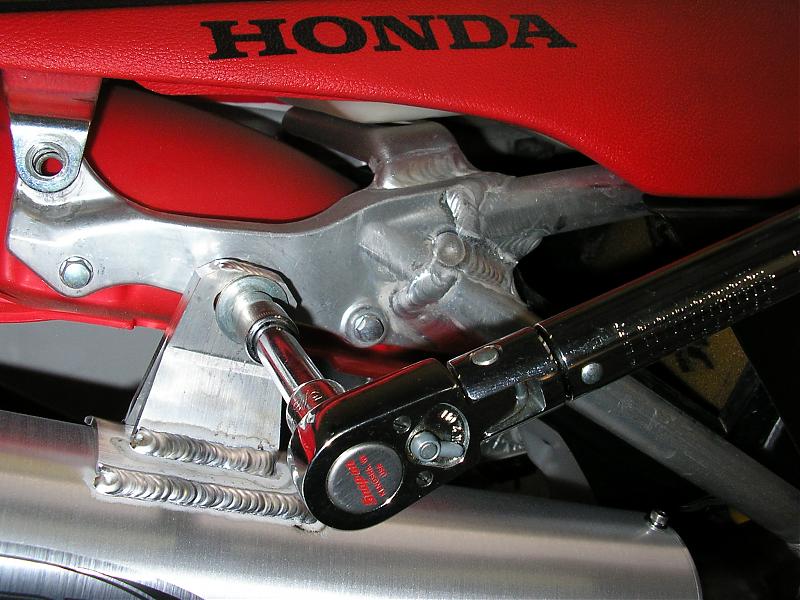

3. Start the mid mount bolt by hand , do not tighten.

4. Start the muffler mount bolt (do not tighten). This is one bolt you don’t want to fall out. If this bolt falls out, you wont know it until the muffler

drops down and gets caught up in the rear wheel, causing major damage and possibly causing you to crash. Because of this, thread lock is recommended.

5. Tighten the header flange nuts using a good torque wrench to 12-14 ft lbs.. Over tightening these nuts will only bend the flange and make it hard to remove later.

6. Tighten the mid mount bolt to 16-18 ft lbs.

7. Tighten the muffler mount bolt to 18 ft lbs.

Every bike is a little different because of the tolerance in the jigs at the factory and the clearance in the mounting holes in the frame and sub-frame. This mounting procedure will insure that the pipe is mounted with the least amount of stress possible and reduce the chance of cracks and breakage.

Maintenance Tips

Today’s high performance 4-stroke engines are hard on muffler packing because of the extreme heat and pulsing . The condition of the packing not only effects sound level output , it can also cause damage to some of the muffler components if enough has blown out, allowing excessive heat build-up in the muffler.

Common signs of overheated muffler

- Burnt sticker or discoloring of anodized cans or end-caps.

- Rivets pulling through or bolts seized.

- A new burning smell you didn’t notice before.

Tips

- Repack often (every 20 - 25 running hours).

- Keep the packing dry. Never wash the bike with out plugging the end of the muffler.

- Use anti-seize on any screws used to hold muffler components together.

- Periodically check all mounting nuts and bolts, including the screws that might be holding the muffler together.

- Most aftermarket exhaust systems use a slip joint where the header joins the mid-pipe. These slip joints do not require a clamp and can become hard to pull apart. A shot of WD40 or penetrating oil will allow easy removal.

Recommended Comments

There are no comments to display.